Shrinkage mechanism of closed cell rubber sponges

Gas permeability characteristic

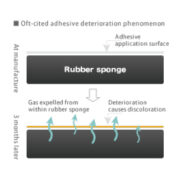

In simplest terms, closed cell sponge, can be thought of as a compound material of hollow rubber balls. One difference from open cell sponge is that the cells are closed off in the form of a clump of rubber balls with no gaps in between. All of the hollow rubber balls, with time, eventually lose their hardness and tension (just like tennis balls or table tennis balls). The “gas permeability” characteristic of rubber causes this to happen. Since the pressure inside the ball is greater than the atmospheric pressure, air from the inside of the ball permeates the rubber to escape to the outside. As a result, the rubber ball loses its firmness with the passage of time. This is the same phenomenon that causes rubber balloons to shrink.

Degree of gas permeability

There are high and low degrees of gas permeability, but all rubbers (compound rubbers and natural rubbers) are permeable, and shrinkage in closed cell sponges cannot be avoided. An example of a rubber with high gas permeability is NR (natural rubber) (applications: rubber balls) and one with low permeability is IIR (Isobutylene-isoprene rubber), used in applications such as inner tubes for tires and rubber tubing.

Shrinkage varies by product type, but the temperatures and humidity of the summer season make it the period that rubber shrinks most easily all year. Storage that avoids high temperatures, high humidity and direct sunlight is required. In winter, shrinkage is comparatively low, but will occur in quite a few NR sponge types. Customers must always use products in a FIFO order.