Solve the Issue of Viscidity

Do Not Kill the Good Quality of the Material

Does sponge only holds viscidity 3 months?

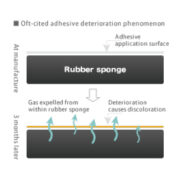

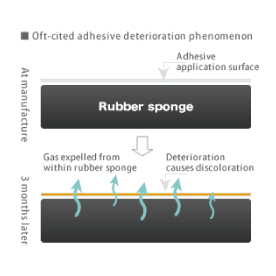

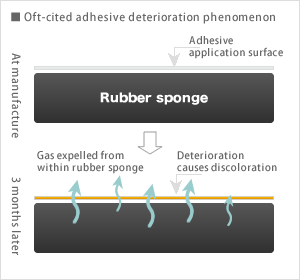

A certain manufacturer purchased rubber sponge with adhesive and stored the leftover sponge in the warehouse. But when checked 3 months later, the viscidity of the sponge had weakened and the rubber sponge was unfit for use. Many attribute the gas expelled from within rubber sponge is the culprit stealing viscidity in most cases, but is this gas the only reason?

High Viscidity Materials

Rubber sponge has a variety of characteristics based on the raw rubber material used in it. For example, CR is a highly versatile synthetic rubber material with exceptional anti-flammable properties and viscidity in particular among the variety of rubber material available. CR is used as a raw material for adhesives and is a highly viscid material itself. High adhesiveness means that that CR is a very good adherend.

Combinations that utilize materials

Where exactly does the adhesiveness issue occur in this kind of CR rubber sponge? One reason is that the characteristics of the material itself are not being best utilized, or are being defeated. The material being used is inherently highly adhesive, so if the material characteristics are capable of being taken advantage of, there would almost never be a problem with adhesiveness. While it cannot be said with certainty, in order to reduce costs, products with an issue have most likely been combined with a number of compounds which trigger the issue. As illustrated in the diagram above, gas is emitted as one result of the materials combined with the raw material at the time of manufacture that causes the adhesive surface to deteriorate. Speaking in terms of cooking, ingredients mixed with the rubber served to kill the good properties of the material.

From a manufacturer’s perspective, the sacrifice of cost for product quality must always be considered in mass production. However, even if product with reduced material properties is developed, the inherent characteristics of the original material itself can still be properly utilized.

(Yoshinobu Miyahara, Miyahara Rubber Industry Co., Ltd.)

【Delivery Case Study #002】 Company B [Machinery and Machine Part Manufacturer]

CR rubber sponge:CR-350

At the factory, a manufacturer client had used another company’s product despite its adhesive defects for many years. They reapplied adhesive, treated the rubber sponge with primer, replaced the direct tension processing with two-sided tape, and tried a number of other workarounds, but none of them solved their problems. When the manufacturer heard that adhesive defects don’t happen with Miyahara Rubber’s product, they came to talk to us and we suggested they try CR-350. They reported back to us that there were zero adhesive defects, and that they could reliably process and deliver a final product.