Solve the issue of uniformity

Carefully create with focus

As a materials manufacturer, we consider performance, quality and costs when we make products. But the foundation for all of this is uniformity. For example, if the quality of the right and left ends of a single sheet of rubber sponge differ, that sheet cannot be considered a material. The performance and quality we strive for break down at this point. In spite of this fact, a certain amount of such defective materials are being put on the market.

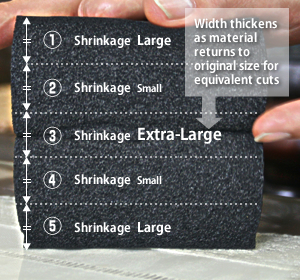

Material cut at different thicknesses

The photo at right is rubber sponge produced by another manufacturer that one of our customers received from a processing company. When pressure is added to the rubber sponge by hand, you can see that the center area marked by the arrow is more concave than other areas. This is the result of a defect in uniformity in this rubber sponge sheet, caused by differing hardness in the precise center of the sheet. The rubber sponge that we deliver is sometimes cut to regulated thickness by a processing company. To cut the sponge requires special techniques; to ensure the blade moves easily through, the material is slightly compressed as it is cut, as shown in the photo. For example, to cut sponge like that shown in the picture into 5 equal parts, even if the blade is inserted as shown, 3 different types of thicknesses will result: (1) and (5), (2) and (4) and (3). Thickness (3) with the depression, in particular, shows a significantly different thickness. Such a sheet clearly does not meet the standard of being called a material (product). Despite this fact, some processing companies in the industry are willing to accept this level of defect in their products. Should this really be acceptable?

Uniform products can be produced if with dedication and attention to detail

Product uniformity is simple common sense in Japan. We have always considered this a matter of course in the manufacture of our products, but were surprised at the number of companies out there who do not share this view. What is the reason for this? To find out, you would of course need to examine the production process. Perhaps there is a problem in production costs or a problem in equipment performance. But, even in spite of such problems, it is clear that the product is not being produced with dedication and attention to detail. No matter what good quality material is used, no matter what good equipment is used, there will be product manufactured that has some kind of slack somewhere. Those involved in the rubber sponge manufacturing industry can make uniform products if they do so with dedication and attention to detail. Doing so links to their pride as a rubber company and as people.

Miyahara Rubber believes that we do not sell “rubber sponge,” but rather “deliver precisely the function” that our customers need.

(Yoshinobu Miyahara, Miyahara Rubber Industry Co., Ltd.)