Our view on defective product

Comments to and customer needs from the rubber sponge industry.

Miyahara Rubber reviews and researches feedback every day.

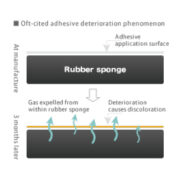

“Before I knew it, the rubber sponge had shrunk.” “As time passes, it loses adhesion.” Have you ever experienced the same things? Most of these issues are caused by the material quality of rubber sponge. And whether the material quality is good or bad depends largely on the total cost of your product.

Shrinkage or poor adhesion issues cannot be identified visually like pinholes can. However, sponges that develop poor adhesion with time clearly encroach on adhesives and sponges with significant shrinkage get smaller over a long period of time. Products that use materials such as these are noted for developing this issue over time. Processing advances and as installation of the end product draws nearer with time; this issue rears its head just as the time for sponge to play its role arrives. This material issue does not stop at just a sponge defect; rather, it now involves peripheral materials and processing costs associated with them, including the adhesive, and becomes a customer claim. The total cost of the product then changes drastically.

Yoshinobu Miyahara, Miyahara Rubber Industry Co., Ltd.

Shrinkage mechanism of closed cell rubber sponges

The clearance size (dimensions) allowed from the differential shrinkage of the material based on differences in rubber material quality and the yield, which is the product defect rate…【Read more】

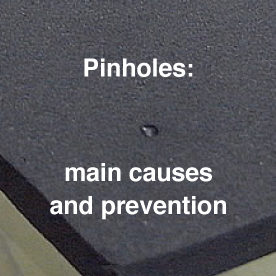

Pinholes: main causes and prevention

Introduction of foreign matter falls into two categories: external origin and internal origin. Foreign matter introduced externally is visually identified during the work process…【Read more】