Pinholes: main causes and prevention

Introduction of foreign matter

Introduction of foreign matter falls into two categories: external origin (already inside purchased material) and internal origin (introduced within our own factory). Foreign matter introduced externally is visually identified during the work process and removed, or may be so small that it cannot be visually identified and extracted and is crushed during the process. The causes of any foreign matter that could be introduced internally must be thoroughly eliminated, but there is no way to defend against foreign matter that falls from the air (such as dandelion seeds or dust), which can only be visually identified and removed or crushed.

Poor dispersion (such as medicines and filler)

Poor dispersion also falls into internal and external origin categories. External origin includes material that should be powdered and includes extremely hard clumps, much like the hard lumps remaining when flour is passed through a sieve. Internal origin causes of poor dispersion include powder lumps that form when rubber and powder are kneaded together. This is similar to the balls of powder that form when flour and milk are mixed to make pancakes. Both companies crush such defects when the material is crushed in the crush process, but there may be matter that does not get crushed inside a hard lump of external origin.

Water mixture

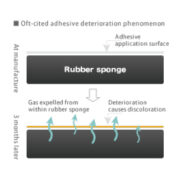

Also of internal and external origins, sometimes water mixture occurs via introduction of material that contains large quantities of humidity from the outside. Water generated inside the factory during kneading may originate from the rubber coolant. Such water mixture appears concurrently with foreign matter to cause even larger pinholes.

Inadequate vulcanization

If temperature, time and pressure are not correct during the baking process, pinholes are produced. When pinholes are found, the values of these items are adjusted.

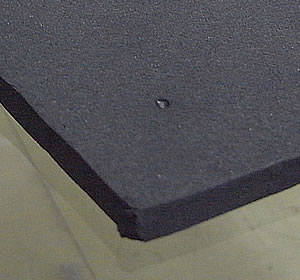

In rubber sponge, pinholes (pockets of trapped air) are one of the 2 major problems on par with shrinkage. Just as with shrinkage, total elimination of pinholes is also nearly impossible to achieve. In the manufacturing process, 0.5 mm foreign matter and poor dispersion sometimes appear as a 10 cm diameter pocket of trapped air. Though Miyahara staff put special effort in working unceasingly to eliminate the sources of pinholes, they cannot be completely eliminated. We strive to improve quality and technology to make them ever smaller and ever fewer in number.